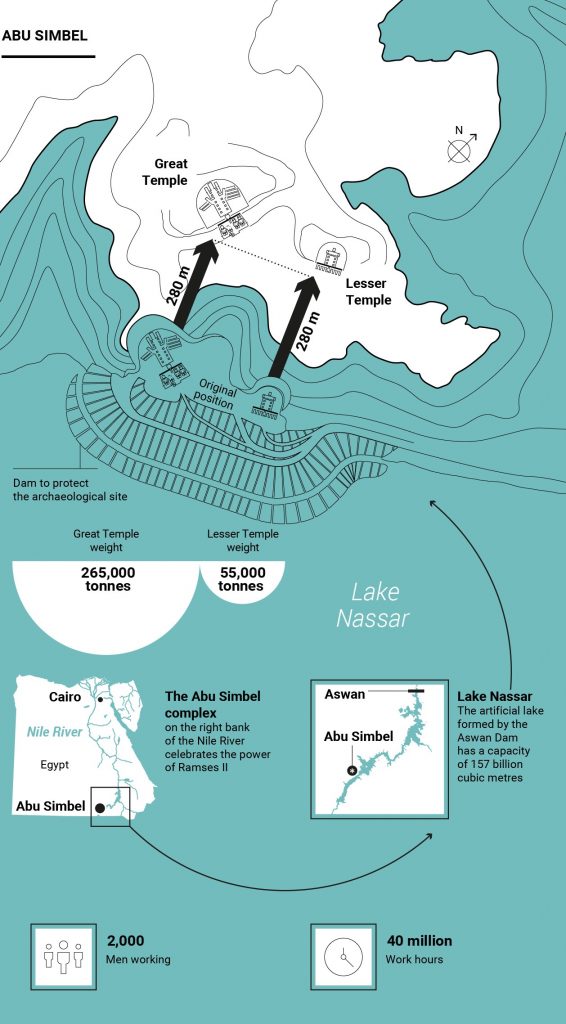

Over 2,000 people working together to save a world heritage site; a one-of-a-kind architectural and engineering challenge involving some of the world's leading construction firms dedicating their top talent to a rare example of international collaboration; a winning bet by the engineering community that believed in the project from the start. All this and more is the story of how the temples of Ramses II at Abu Simbel in Egypt were saved from destruction when the rising Nile waters from the construction of the nearby Aswan High Dam threatened to put thousands of years of history at risk.

On January 9, 1960, three months after construction began on the dam, the United Nations Educational, Scientific and Cultural Organization (UNESCO) launched a world-wide call for help: if action was not taken before the dam’s reservoir was filled with water, these priceless artistic treasures belonging to all of humanity risked disappearing forever. The world’s largest construction companies answered the call, and started working on a solution to move the temples to safety.

The challenge was immense: the two temples weighed 265,000 and 55,000 tonnes each, and no one – until then – had ever undertaken a project of this magnitude. A project presented by a European consortium of construction companies was eventually chosen in 1963. It called for cutting up the temples and the sculptures into blocks, taking them apart, moving them, and putting them back together on a nearby artificial hill paved with the original stones. The basic idea was to dismantle the temples and move them to a place where water could not damage them. The consortium included Salini Impregilo, tasked with the job of building the artificial hill, breaking up the temples into more than 1,000 blocks, and carrying out the reconstruction.

The first trial took place nearly two years later, on May 21,1965. A block of the Great Temple was successfully carved out and moved using a procedure that was demonstrated to be safe. This was proof that the project was on the right track, convincing the companies and UNESCO to proceed.

The rescue operation took place in three phases. The first lasted from the spring of 1964 to the spring of 1965. During the course of the year, the partners built a dam that was 370 metres long and 25 metres high to protect the temples from the reservoir’s rising waters, using 380,000 cubic metres of rock and sand, and an 11,000-cubic-metre stack of sheet metal. Along with the dam, the site was protected by building a drainage system, with wells and underground channels.

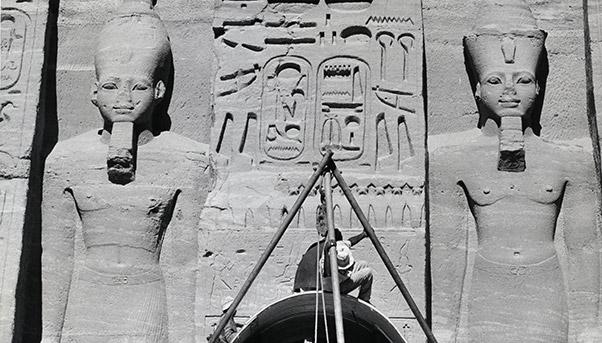

The second phase was the most crucial because it called for the dismantling of the temples. This phase began at the start of 1965 and ended in April of the following year. Dismantling began at the top of the temples, while their facades were protected by sand cushions to prevent fragments from falling and causing damage. The Great Temple alone was covered with 19,000 cubic metres of sand. The interior of the temples was bolstered by a steel scaffolding.

The most delicate part of the rescue could begin. The blocks that comprised the temples, made of sand and rock, had to be cut into pieces. To accomplish this task, specialized marble cutters were summoned all the way from Carrara in northern Italy. Experts followed a strict set of guidelines: blocks from the ceiling could not weigh more than 20 tonnes, and blocks from the façade could not exceed 30. Moreover, the maximum size of the façade blocks was not to be larger than 15 square metres, 10 square metres for the ceiling, and 12 square metres for the temple rooms.

In May 1965, a crane hoisted the first stone block into the air, kicking off the start of the dismantling. The stones were loaded onto enormous trucks to be transported to a 44,000-square-metre area designated as a depository. Here, the cut sections were placed with care and each marked in such a way as to be easily identified when the time came for them to be reassembled. In order to avoid ruining the blocks, they were constantly treated with doses of synthetic resin.

When the last of the temple blocks had been moved, the rebuilding work began in January 1966 and lasted until September 1968.

In this third and last phase, surveyors went to work to guarantee that each block was perfectly positioned, which at times could take several hours. The blocks were placed on the ground by cranes, and then moved into their exact position by hydraulic lifts. Once the last piece of the temples was put into place, it was time to re-construct the surrounding area exactly the way it had been. So the rocks surrounding the façade were restored, and artificial hills created.

When the works were completed around five years later, the temples were returned to their ancient splendor, the only difference being they were 280 meters inland and 65 meters higher than before. This incredible achievement required 40 million hours of work, and an investment of $40 million (in 1960s dollars).

Moreover, an entire village needed to be created from scratch, with warehouses, offices, storage, living quarters for the workers, a hospital, social centers, and even an airplane runway. All of the equipment – from digging machines to pneumatic drills to dump trucks – had to be brought from Europe by sea.

It was a race against time that inspired a great deal of teamwork, a unique mission where scientific and engineering excellence were placed at the service of saving one of humanity’s historic and artistic treasures.