From the floating construction site in Vado Ligure, the silhouette of the new breakwater in Genoa, currently under construction, is almost invisible. Yet, just a few days ago, the third reinforced concrete caisson set off from these industrial docks, located a few hundred meters from Savona, and was then positioned next to the first two massive blocks that are shaping the breakwater.

To give an idea of the complexity of the operations, moving such a caisson is like transporting an eight-story building by sea. This “giant,” 21 meters high and 40 meters long, is not one of the largest among those that will form the breakwater, some of which will reach lengths of up to 66 meters. On July 23 at 7 PM, the floating caisson, hollowed inside like a beehive, set sail, towed by one of the tugboats servicing the site, embarking on a journey of over 16 hours. The next day, it was positioned next to the other two.

Genoa’s new breakwater, an eight-story building at the bottom of the sea

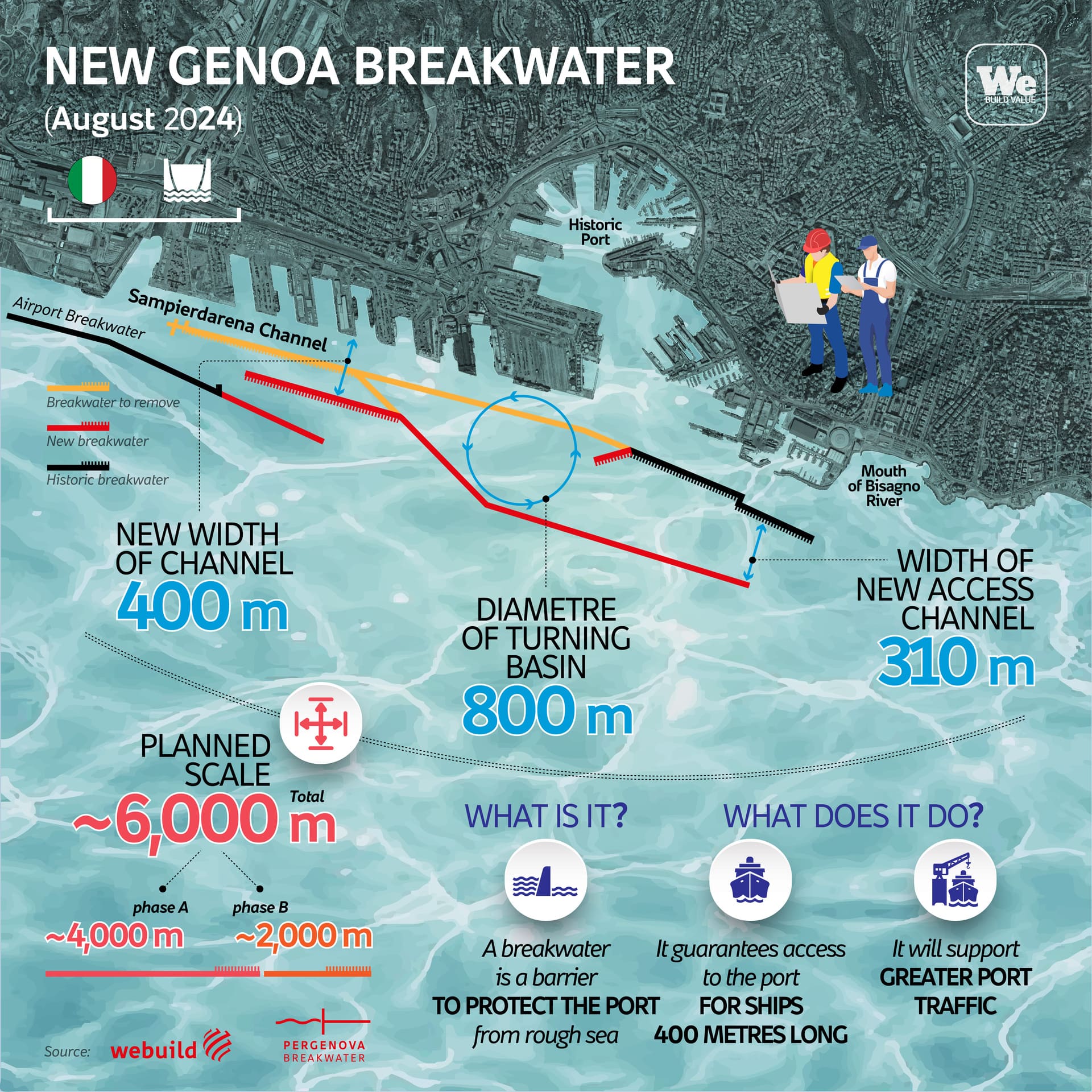

Placing an eight-story building at varying depths between 20 and 50 meters below the sea surface is no easy feat. At the marine construction site off the coast of Genoa, men and boats are operational day and night to complete the operation and add the third caisson to the breakwater. Over 90 caissons will form the first 4 kilometers of the new barrier, allowing the port of Genoa to accommodate even the largest ships in the world, those up to 400 meters long.

The caisson has a cellular shape, meaning its internal section consists of cells, specifically 45 cavities within the structure. Once positioned next to the others, the sinking process begins with seawater. Through a series of pipes, an average of 16,000 cubic meters of water is pumped into the caisson. Once filled, the caisson starts to sink and is guided into position next to the other two.

From this point, other operations commence, such as analyzing the position and verifying the solidity of the caisson and its response to sea pressures. Once completed, the final phase begins: the water that enabled the caisson to sink is replaced with rocky material. An average of 27,000 tons of rock is needed to fill each of these massive blocks, rock sourced from quarries scattered along the Mediterranean coast and transported to Genoa by a fleet of boats. This is the last step in completing the process of placing the breakwater giants.

The foundations that support the giants

The caissons of the Genoa’s new breakwater are not placed directly on the sea floor. There is a complex process of creating the foundations on which the breakwater will be built, a process that goes hand in hand with the placement of the caissons and is still ongoing at the marine construction site in Genoa. Leading the operations are two enormous vessels: the Venezia, 66 meters long and 24 meters wide, and the Boa Barge 34, which is 140 meters long and 35 meters wide.

These vessels started as simple floating barges, gradually equipped with all the necessary tools to complete the work. Essential elements of this equipment are the enormous cranes used for the breakwater’s foundations. The “Venezia” has two cranes, each about 45 meters high, while the “Boa Barge 34” has four, reaching up to 65 meters. Attached to the crane cables is the vibroflot, a special rod 18 meters long and weighing between 14 and 20 tons, equipped with holes from which air mixed with water is pumped at high pressure and a vibrating head about 2.5 meters long.

Once gravel is laid on the sea floor, the vibroflot creates holes into which the gravel is compacted, forming buried columns with a diameter of approximately 110 cm and a length varying between 6 and 12 meters. This process constructs the 70,000 columns that form the core of the foundation of Genoa’s new breakwater, the base on which the concrete giants rest after their long journey at sea.